Why Learn to Machine Knit?

To learn to machine knit is not as easy as many people think. It takes time and patience. So, why bother? It is an immensely satisfying pastime. With a knitting machine and yarn you can create fashion items for you and your family or furnishings for your home. Once you have mastered the basic techniques, it is an easy skill to develop and before you know it you will be an expert machine knitter.

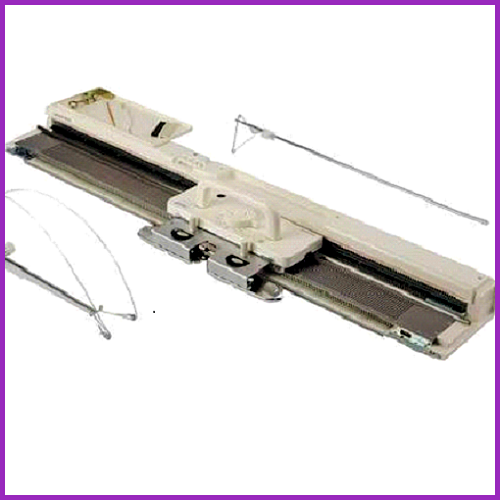

The Knitting Machine

A knitting machine is a device used to create knitted fabrics in a semi- or fully automated fashion. There are numerous types of knitting machines, ranging from simple looms with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity.

Knitting machines can be used to produce knitted textiles with scope to explore:

- using different fibres – wool, plant fibres, synthetics etc.

- using texture – either from variations in yarn or via the machine’s patterning facility

- using colour – using patterns on the machine

- the patterning functions of the machine: punch cards, for example, use a simple binary system to instruct the machine – a forerunner of modern computers; while electronic machines use the same system in a different format

- interactive work using computer software to develop patterns

They have many advantages: they are fairly light, easy to set up, fairly easy to maintain, and quite versatile

Pattern stitches can be selected by hand tooling of the needles, or with push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers. To produce larger and more complex knitted items such as garments, domestic machines, with either flat or circular beds that produce rectangular or tubular fabrics are needed. Double bed machines have two flat beds facing each other, in order to produce purl and plain rib fabrics plus a variety of multi patterns. Ribbing attachments can be added to single bed machines to achieve a similar result. Machines typically use up to 200 latch-hook needles to hold the stitches in fine, standard, mid-gauge or bulky gauge needle. A carriage or cam box is passed across the bed of needles causing the needle movements required to produce each next stitch. By means of various selection methods, e.g. punch cards, particular needles can be caused to travel by alternate pathways through the cam box. Thus needles will knit or not, and the un-knitted yarn portions will lie under (slip stitch) or over the needle or be held in the needle hook (tuck stitch). Needles can be placed in holding position to allow short row shaping. In the most modern machines, punchcards have been replaced by computer control. Automatic patterning machines can knit two-colour Fair Isle patterns automatically, and have machine stitch patterning features such as plating and knitweaving.

Abbreviations

To make the reading of knitting patterns more straightforward, the names of knitting stitches and instructions are often abbreviated. Instead of repeating ‘stockinette stitch’ for instance, the abbreviation ‘st.st.’ is used. This is helpful and makes patterns easier to follow. Most knitting patterns and books contain a glossary of terms used including any special or unusual abbreviations.

Blocking

Some machine knitted items benefit from being blocked. Blocking a finished piece of knitting entails gently wetting the item and then pulling it to shape on a flat surface. The item may need to be pinned to stop it from springing out of shape. A knitting pattern will give any special instructions required for blocking.

Machine Knitting Symbols

Some machine knitting patterns are presented using knitting symbols. Each stitch has a unique symbol and this is used to show how a design is created. Many patterns that feature symbols also have a written version. Symbol knitting is useful as it transcends language making a project open to knitters the world over.

Machine Knitting Terms

Machine knitting has a language all of it’s own. When you learn to knit on a machine the first thing you will have to do is become familiar with machine knitting terms such as ribber and tuck stitch.

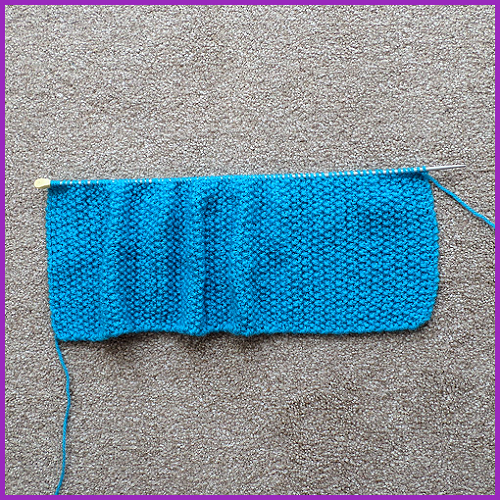

Tension or Gauge

Machine Knitting gauge is very important. This measures the number of stitches and rows to 10 cm. Checking knitting gauge is necessary when making an item that needs to be a set size. If there are too many stitches and rows then the item will be too small and a larger tension dial setting should be used. Most machine knitting patterns will give a stated gauge and before starting the pattern, a test square should be worked to check gauge. Machine knitters can use the green or the blue ruler technique to measure their tension.

Plating

Plating refers to knitting with two strands of yarn that are held in such a way that one is in front of the other. Plated effects can be particularly striking in a ribbed fabric.

Knitweave

Knitweaving refers to a technique in which a separate piece of yarn, often heavier than the knitted fabric, is carried along and caught between stitches to produce an effect like weaving. With knitwoven fabric, the purl side (usually the wrong side) is the right side of the fabric.

Lace Carriage

The fine and standard gauge models have the option of a lace carriage, where stitches can be transferred from one needle to the next. The yarn passes through a tensioning mechanism and down through the knit carriage, which feeds the yarn to the needles as they knit.

Yarns

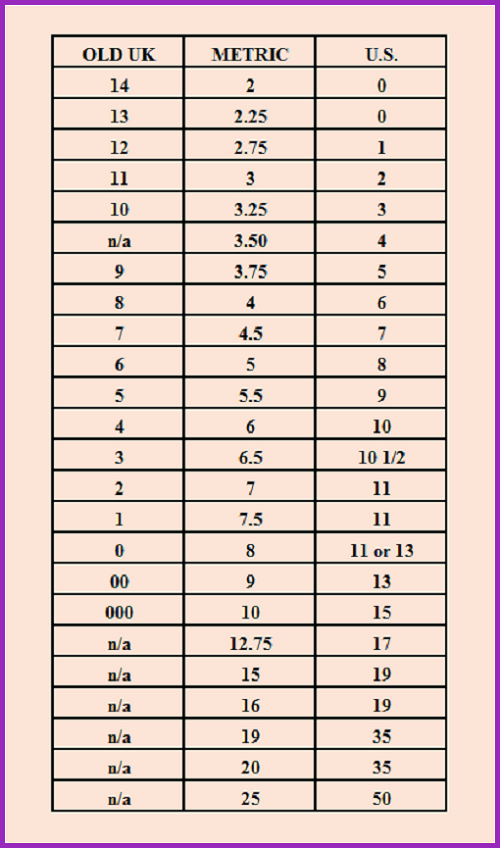

Yarn and wools are grouped together according to thickness. This means that all yarns that are double knitting weight will be the same thickness regardless of brand or manufacturer. This standardisation of yarns is a useful way to ensure that yarns can be substituted in crochet patterns without altering the finished dimensions of a project. Machine knitting yarns are usually wound onto cones and follow the industrial weighting system.

Loom Knitting

Hand Knitting Looms allow you to knit without needles. Knitting looms come in a variety of shapes and sizes with pins mounted in rows on a firm base. Yarn is wound around the pins; various patterns of winding produce different textured knitting. A needle or special tool is then used to transfer the loops of yarn from around the pins, either off the pins or to other pins, to produce the knitting.

Machine or Hand Knitting

Machine knitting proceeds more quickly than in hand knitting, where (usually two) straight needles are held in the hand and each stitch is manipulated individually across the row. Knitting machines work an entire row of loops in a single movement.

The fabric produced using a knitting machine is of a more even texture than hand-knitted fabric, which is particularly noticeable on large areas of plain stockinette stitch, and can be an advantage. Some stitch patterns (e.g., tuck stitches) are much easier to produce with a knitting machine. Others (e.g. garter stitch) can also be produced with machine knitting but can take a little longer but still much faster than hand knitting. The standard gauge 200-needle machine can knit the finest yarns up to a good sport-weight, while the heavier yarns knit better on a mid-gauge or bulky knitting machine.

Machine knitting saves a considerable amount of time but does require learning to operate the machines correctly. Often, with machine knitting there is more finishing to do. It is more likely that a machine knitted project will require to be blocked and steamed than a hand knitted project. Most if not all hand knitting patterns can be worked up on a machine, either identically or in a similar design.

However, hand knitting is more portable and sociable than machine knitting. Hand knitting can be very relaxing and some people find it has a meditative quality. It is more expensive to start machine knitting because you have to buy an expensive machine. With hand knitting you can start with a pair of knitting needles and a ball of yarn. The choice is yours!